Innovative Ideas for Disposing PPE in Sustainable Ways

With the global surge in Personal Protective Equipment (PPE) usage during recent years, a new challenge has emerged: how to dispose of used PPE sustainably. From face masks to gloves and gowns, billions of single-use PPE items end up in our landfills, waterways, and natural environments. This in-depth article explores innovative ideas for disposing PPE in sustainable ways and outlines how individuals, communities, and industries can embrace eco-friendly PPE disposal practices for a greener planet.

Understanding the Urgency: PPE Waste and Its Environmental Impact

The worldwide demand for PPE has risen dramatically, especially due to global health crises. While essential for protecting public health, PPE waste management has become a massive environmental burden. Commonly discarded masks, gloves, and gowns can take hundreds of years to decompose and often release microplastics and toxins into the ecosystem.

- PPE is primarily made from non-biodegradable materials such as polypropylene and polyethylene.

- Improperly disposed PPE often ends up in oceans, affecting marine life and degrading water quality.

- Incineration of PPE can emit dangerous chemicals and contribute to air pollution.

Given these challenges, there is a critical need for sustainable PPE disposal solutions that address both infection control and environmental preservation.

What Qualifies as PPE and Why Its Disposal is Challenging

Personal Protective Equipment includes surgical masks, respirators, gloves, gowns, face shields, and goggles--all designed for single use and made primarily of plastics. Because of the potential contamination risk, especially from healthcare settings or public environments, simply recycling PPE is rarely safe or feasible with current processes. This makes the quest for sustainable PPE disposal ideas even more complex.

1. Recycling PPE: Technological Innovations

Advanced Mechanical Recycling

Standard household recycling programs cannot handle contaminated PPE, but some companies have developed specialized recycling systems. These facilities use advanced mechanical processes to:

- Sterilize PPE waste with high heat or chemicals to eliminate pathogens.

- Sort and shred the material into smaller, manageable pieces.

- Process shredded plastics into pellets, which are used as raw materials for new products.

For example, TerraCycle and other innovative enterprises offer mail-back programs for masks and gloves, turning used PPE into building materials, outdoor furniture, and more.

Chemical Recycling and Pyrolysis

*Chemical recycling* transforms PPE waste at a molecular level, converting plastics back to their original monomers or fuels. In particular, pyrolysis--heating plastics in the absence of oxygen--can break down PPE into usable oils, fuels, or raw materials for new plastics. This innovative PPE waste disposal method reduces volume, recycles carbon, and decreases demand for virgin fossil resources.

2. Upcycling: Giving PPE New Life

PPE in Construction and Road Building

A ground-breaking approach involves incorporating sterilized PPE into construction materials. Some researchers have demonstrated that shredded face masks can reinforce concrete or asphalt, improving strength and flexibility while diverting waste from landfills.

- Road surfaces enhanced with PPE plastics become more durable and less prone to cracking.

- Upcycled PPE in bricks or tiles reduces the demand for natural raw materials.

Such eco-friendly PPE disposal methods offer multiple environmental and economic benefits.

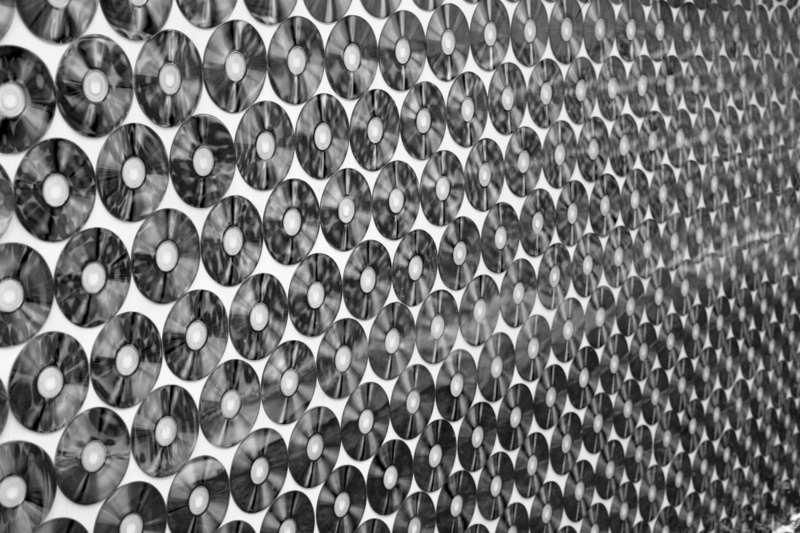

Create Art and Educational Objects

Creative communities and educators have begun transforming clean PPE into art installations, educational exhibits, or recycled crafts. These projects raise awareness about PPE pollution and offer interactive opportunities to learn about sustainability.

3. Biodegradable and Compostable Alternatives

One key to sustainable personal protective equipment disposal is reducing reliance on traditional plastics. Recent breakthroughs include:

- Biodegradable face masks made from plant fibers like bamboo, cotton, or hemp that break down safely in composting environments.

- Compostable gloves manufactured from natural latex or cornstarch-based biopolymers, which degrade naturally.

When these products reach their end of life, they can be disposed of in industrial composting facilities instead of landfills, closing the loop on waste.

4. Decentralized Take-Back and Collection Schemes

Setting up dedicated PPE waste collection points in hospitals, offices, schools, and public spaces can dramatically improve safe handling and enable downstream recycling or treatment. Best practices include:

- Clearly labelled bins to prevent cross-contamination with regular recyclables.

- Scheduled pickup services by specialized waste handlers.

- Awareness campaigns to educate the public on sustainable PPE disposal options.

Such focused collection systems streamline PPE aggregation and facilitate the adoption of innovative disposal methods for masks and gloves.

5. Energy Recovery Through Safe Incineration

Incinerating PPE at high temperatures can recover energy and safely destroy pathogens, provided emission controls are in place. Modern waste-to-energy plants capture heat generated during incineration to produce electricity or steam for district heating--an efficient alternative to landfilling.

- Strict filters and scrubbers remove toxic byproducts from emissions.

- Energy produced can offset the carbon footprint associated with PPE manufacturing and use.

This sustainable disposal method for PPE is especially practical for large urban centers with significant health or industrial waste streams.

6. Public Engagement and Behavioral Solutions

Innovative ideas for disposing PPE in sustainable ways must consider the human factor. Changing behaviors through education and incentives is pivotal:

- Awareness campaigns in public places, hospitals, and workplaces emphasizing the environmental consequences of improper PPE disposal.

- Deposit-return schemes for used PPE, where users can return single-use PPE for safe recycling and receive discounts or tokens.

- Community clean-up drives focusing on collecting improperly disposed PPE and safely channeling it into recycling or safe disposal streams.

Encouraging individuals to make mindful choices and supporting collective action ensures long-term, widespread adoption of sustainable habits.

7. Embracing Reusable PPE Solutions

Transitioning, where possible, from single-use to reusable PPE solutions can drastically cut down waste. For example:

- Durable masks with replaceable filters, made from washable fabrics.

- Reusable gowns and face shields that can be sterilized and used multiple times in healthcare and industrial settings.

When paired with robust cleaning protocols, reusable PPE is both cost-effective and environmentally responsible, significantly reducing the total volume of PPE that must be disposed of.

8. Policy, Research, and Industry Collaboration

To scale sustainable PPE disposal, involvement from governments, researchers, and private sector innovators is crucial.

- Regulatory frameworks that set clear standards for PPE collection, recycling, and end-of-life management.

- Grants and incentives to support research into new materials and advanced recycling technologies.

- Public-private partnerships for infrastructure investment and public outreach.

Such collaboration can accelerate the mainstream adoption of eco-friendly PPE disposal practices and open new economic opportunities in the evolving green sector.

Summary: The Path to Sustainable PPE Disposal

As the world continues to rely on personal protective equipment, we cannot ignore the mounting environmental impacts. Responding to this urgent issue, innovative ideas for disposing PPE in sustainable ways are emerging at the intersection of technology, creativity, and community action.

Key takeaways:

- Specialist recycling and upcycling methods can divert huge volumes of PPE from landfills and oceans.

- The rise of biodegradable PPE materials offers hope for future waste reduction.

- Comprehensive collection systems enable safe handling and downstream innovation.

- Public engagement--through education and incentives--drives participation.

- Government, industry, and research must collaborate to scale impactful solutions.

From sterilized recycling and creative upcycling to the development of compostable alternatives, *the future of sustainable PPE disposal* is bright, provided we act quickly and collectively. By embracing these diverse strategies and fostering collaboration at all levels, we can turn the tide on PPE pollution and pave the way toward a safer, greener, and more resilient world.

Frequently Asked Questions: Sustainable PPE Disposal

Can used PPE be recycled in regular household recycling bins?

Generally, used PPE should not be placed in household recycling bins due to contamination risks. It should instead be sent to specialized recycling or disposal programs designed for medical and contaminated waste.

Are there biodegradable alternatives to traditional PPE?

Yes! Biodegradable face masks and gloves made from sustainable materials are increasingly available. These can be composted industrially and break down much faster than their plastic counterparts.

How can communities encourage proper PPE disposal?

By installing designated disposal bins, hosting clean-up events, sharing educational materials, and offering incentives, communities can play an essential role in promoting responsible and innovative PPE disposal methods.

By applying these actionable strategies, every individual and organization has a role to play in advancing sustainable PPE disposal for a healthier environment and a better future.